David Burns, the world’s most experienced airship test pilot, puffs out his cheeks. “The possibilities are endless,” says the Scotsman. His latest vessel, the Airlander 10, can stay aloft for 21 days. It requires no runway nor aircrew and can cruise silently in any direction at speeds of up to 87mph. “From here to Cape Town would be nice,” muses Burns at the Airlander’s base near Bedford. “Congo; safari; you could swoop over migrating wildebeest or sail slowly past every European capital, stop at each one to take on salamis, cheeses, champagnes…”

If Burns is nervous, he doesn’t show it. In a few short hours, the chief test pilot for Hybrid Air Vehicles (HAV) will captain his ship during the most celebrated flight of its life. In front of assembled investors, Burns will perform a thorough second test in what is easily the world’s longest aircraft. If it goes well, bids will be made, orders will be processed and a second airship revolution will sweep the globe.

Does Burns carry a lucky charm? “Don’t be silly now. It’s true flight up there. The airship is running silently. You can open the cockpit window, look down on Earth and hear the birds sing. I’ve got a parachute of course, but it’s just regulations.” (In actuality, Burns’ 100-minute test flight in late August 2016 was a roaring success, aside from a nasty nose bump on landing.)

Though, being filled with helium, Airlander is already buoyant, the airship’s hull creates 40% of its lift.

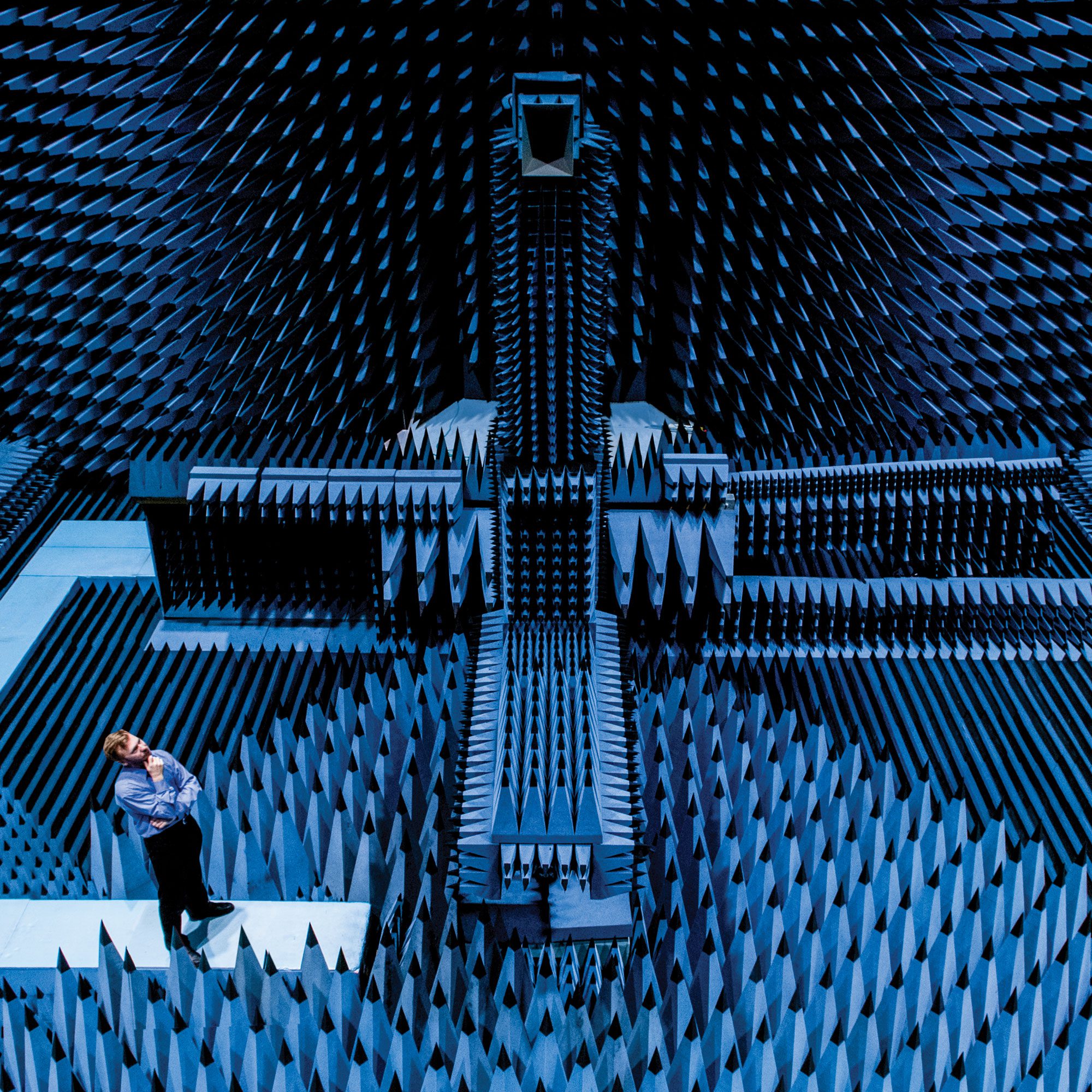

Before we examine the Airlander up close, we sit in the hangar that, until last week, housed the gargantuan vessel. At 210 metres long and 52 metres high it gapes and soars like a cathedral of modernity. Situated in an RAF balloon-testing base that was rendered off-limits to the public – the ‘Area 51’ of rural Bedfordshire – the history of the Grade II-listed building outlines neatly the airship industry’s first golden age.

The story starts a century ago. Balloonist brothers Eustace and Oswald Short were commissioned to build two airships to counter the Zeppelin menace of warring Germany. By 1916 the brothers had constructed their work hangar at Cardington, 56 miles north of London. A workers’ village, named Shortstown, was built alongside. In July 1918, the 187-metre-long R31 drifted out of the hangar like a giant cigar. Armed to the teeth with cannons, and twice as long as today’s Airbus A380, it must have terrified locals more than the deadly Luftstreitkräfte, though it never saw action. In 1930, the even longer R101 emerged from the Shorts’ Cardington hangar. This passenger-carrying craft crashed on its maiden voyage to India and put an end to Britain’s airship industry. Until now.

It’s the longest aircraft in the world, ready to set more records than Concorde yet its presence is bashful, modest, perhaps embarrassed by its own simplicity.

“Two factors that have permitted the development of the Airlander,” claims Chris Daniels, HAV’s head of partnerships and communications. “First is computer power, so we can test anything in theory before we leave this hangar. Second is new materials, so we can fly lighter, faster and safer than people dreamt of, even a decade ago.” HAV purchases unbreakable carbon composite struts from the same firm that supplies Formula One cars, and the Airlander 10 is skinned with a high-tech fabric woven with Tedlar, Mylar and Vectran, the same lightweight, high-stress sheeting used in America’s Cup sails.

Last week Daniels delivered a lecture during the Rio Olympics. “Several sailing teams complained about the noise and turbulence from TV helicopters. But the Airlander could stay airborne for the entire duration of the Olympics’ sailing events and have almost limitless cameras aboard.” The Tokyo 2020 games could easily feature an airship emblazoned with the Olympic rings, likely adjoined by the logos of global sponsors Samsung and Coca-Cola. To quote test pilot Burns, the possibilities are endless.

“Aside from acting as a frontline surveillance craft, we envisage two other markets for today’s airship industry,” says Daniels. By reducing the size of the fuel tanks the Airlander 10 becomes a glorified cargo truck – one that can transport 10 tons of payload anywhere on the planet. “Over 50 per cent of people live out of reach of a paved road,” he explains. “If you want to deliver a hydroelectric plant to the Brazilian rainforest, or hover with supplies next to an Afghan mountain top, Airlander is for you.”

NUMBERS

38,000

Envelope Volume (metres cubed)

4880

Altitude Ceiling (metres)

10,000

Payload Capacity (kilogrammes)

But replace cargo with passengers, and you have a whole different ball game. “From sightseeing flights over Bedfordshire to internal layouts with bedrooms and panoramic lecture theatres for use over the subcontinent, we can tailor the ship to any use,” Daniels says. The airship was only released from the Cardington hangar a week ago. Up close its beauty is subtle but contradictory – it is brutal yet refined, massive yet weightless. Thanks to its helium-topped ground weight of a single ton, it is as easy to push as a Mini Cooper with the handbrake off. Evidently – as we were regaled with the ship’s parentage, birth, growth and release – the Airlander 10 is easy to poeticise. It flies silently as the bird; as swift as the breeze. Tethered before its test flight, it quivers and shivers in the morning sun. It’s the longest aircraft in the world, ready to set more records than Concorde (including longest flight and farthest flight, to name but two), yet its presence is bashful, modest – perhaps even embarrassed by its own simplicity.

David Burns, Airlander’s chief test pilot, in the 210 metre-long Cardington Airship Sheds. Having been repurposed in the century since their construction for, among other things, film studios and model aircraft flying, the hangars returned to their original purpose in 2007 when Hybrid Air Vehicles established themselves there.

“The technology is so simple it’s unbelievable,” says Daniels. There are no wires, rivets or struts inside, just the same lighter-than-air technology from a century ago. The absence of heavy materials means these airships can be delivered to order in as little as 12 months. While Boeing’s 787 Dreamliner cost a reported $32bn to produce, the Airlander 10s needed just £3.5m to see it through the final months of production: a sum which was raised by crowdfunding. There’s something winsome about being part of such a futuristic yet time-honoured machine. Like most things, success will boil down to the bottom line. Back in the hangar it is make-or-break week. Phones ring. Sensitive screens are shielded from us and we’re encouraged to leave before the final test briefing. At £25m each (the price of a business jet but with a quarter of the running costs), HAV hope to sell 100 of these ultra-efficient airships over the coming decade. If the orders stockpile they can fulfil their dream of the Airlander 50, the ne plus ultra airship that can deliver the equivalent of 50 hatchback cars or sail 400 passengers safely through the ether. Never has the future of aviation depended so much on hot air.